Jacketed Enameled Wire-Winding Wire Application Paint Removing And Recipe

What is enameled wire for?

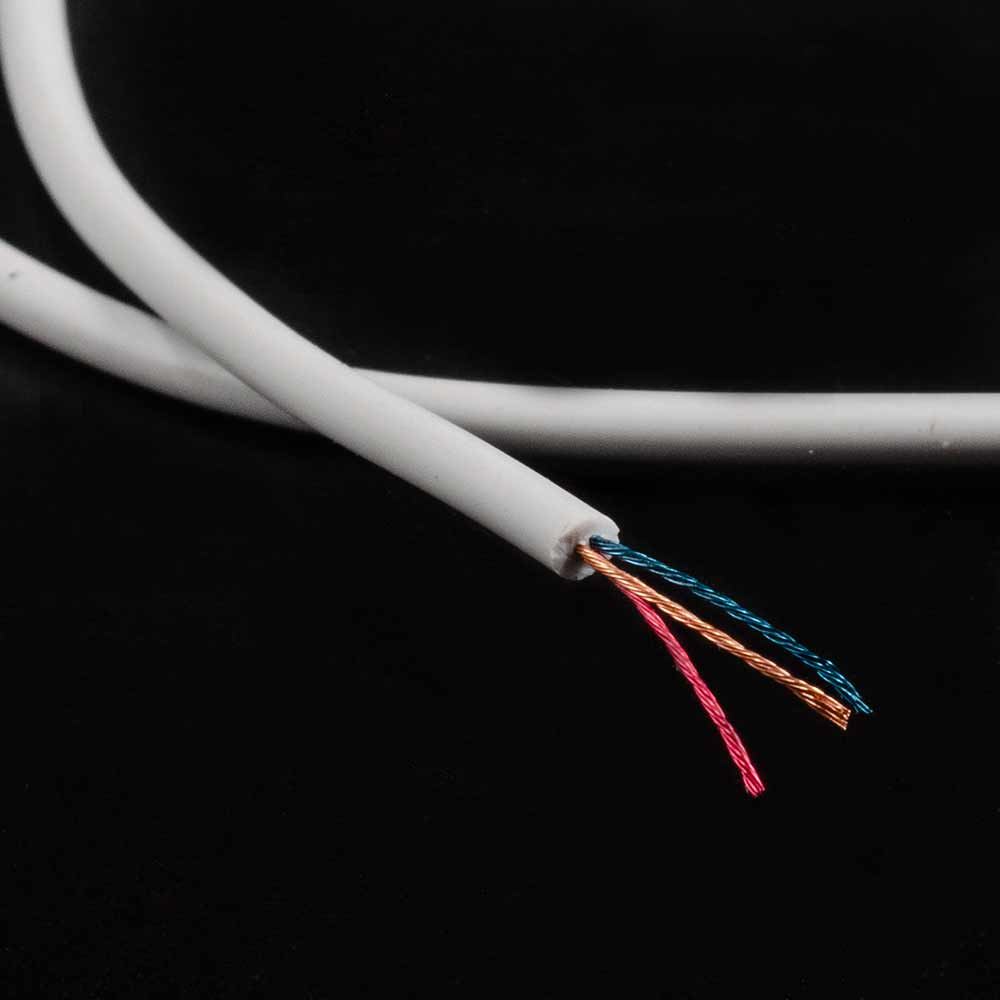

Enameled wire (also called varnished wire ) is mainly used as winding wire. It is widely used in the field of household appliances, electric tool industry, automobile industry, electric power industry, and instrumentation industry. It is often used as compressor winding, motor winding, coil, etc. It should be noted that although the enameled wire is also a kind of wire, its insulation layer is very thin and cannot be used as an ordinary wire. If it is used as a wire, it must be covered with an insulating tube.

enameled wire has two main types:

enameled copper wire

(You maybe interested in “what is the difference between enameled copper wire and enameled aluminum wire in terms of their properties and application“

enameled aluminum wire

Enameled wire is a kind of winding wire, which is composed of conductor and insulating layer. It has four major properties: mechanical properties, chemical properties, electrical properties and thermal properties. It is widely used. So what are the uses of enameled wire?

1. Household appliances

Used as compressor windings on refrigerators, freezers, air conditioners, and cryogenics; motor windings for washing machines and vacuum cleaners; color TV deflection coil windings; electronics, inductors, wireless chargers for mobile phones, etc.

2. Power tool industry

Stator and rotor coils of motors such as electric hammers, chainsaws, and cutting machines.

3. Automobile and motorcycle industry

Widely used in coils of automobile generators, new energy vehicles, electric two-wheel, three-wheel, four-wheel generators, starter motors, ignition devices, power steering wheels, oil gauges, etc.

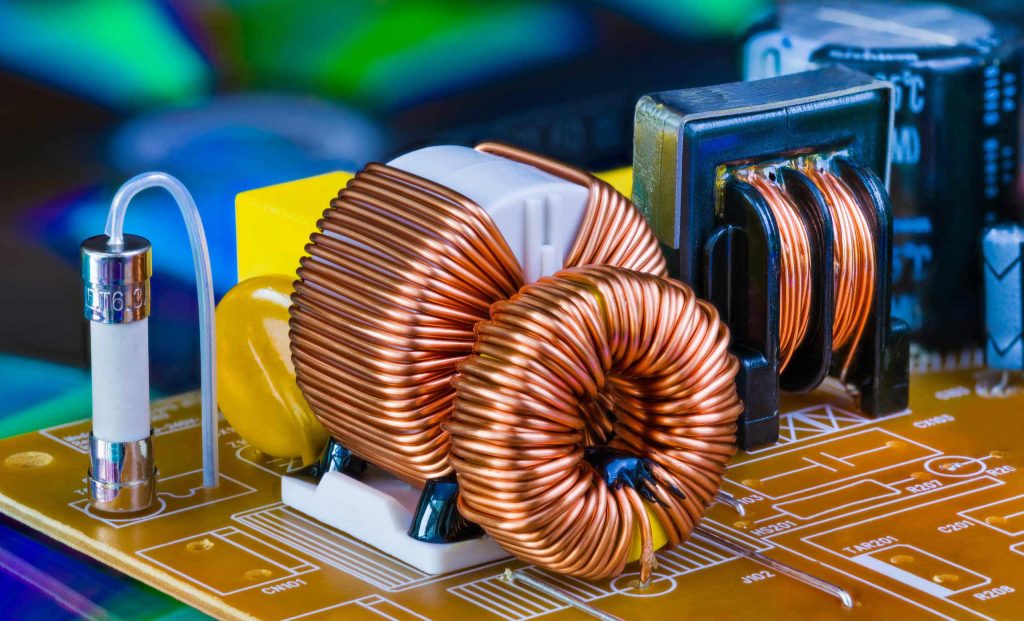

4. Transformer winding coils in the power industry.

enamelled wire is an important component in the power industry, and its use in transformer winding coils plays a critical role in ensuring the efficient and reliable distribution of electrical power. Its durability, high electrical conductivity, and resistance to harsh environments make it a trusted and widely used material in a variety of applications

5. Inductance coils in the instrumentation industry

Enamelled wire is also widely used in the instrumentation industry for inductance coils. The insulation layer of the wire provides excellent electrical insulation, allowing for precise control of the magnetic fields generated by the coil. The wire’s high electrical conductivity and low resistance also make it an ideal material for inductance coils, which are used in a variety of instruments and devices, such as sensors, transformers, and filters. The durability and resistance to harsh environments make enamelled wire a reliable and cost-effective material for inductance coils in the instrumentation industry.

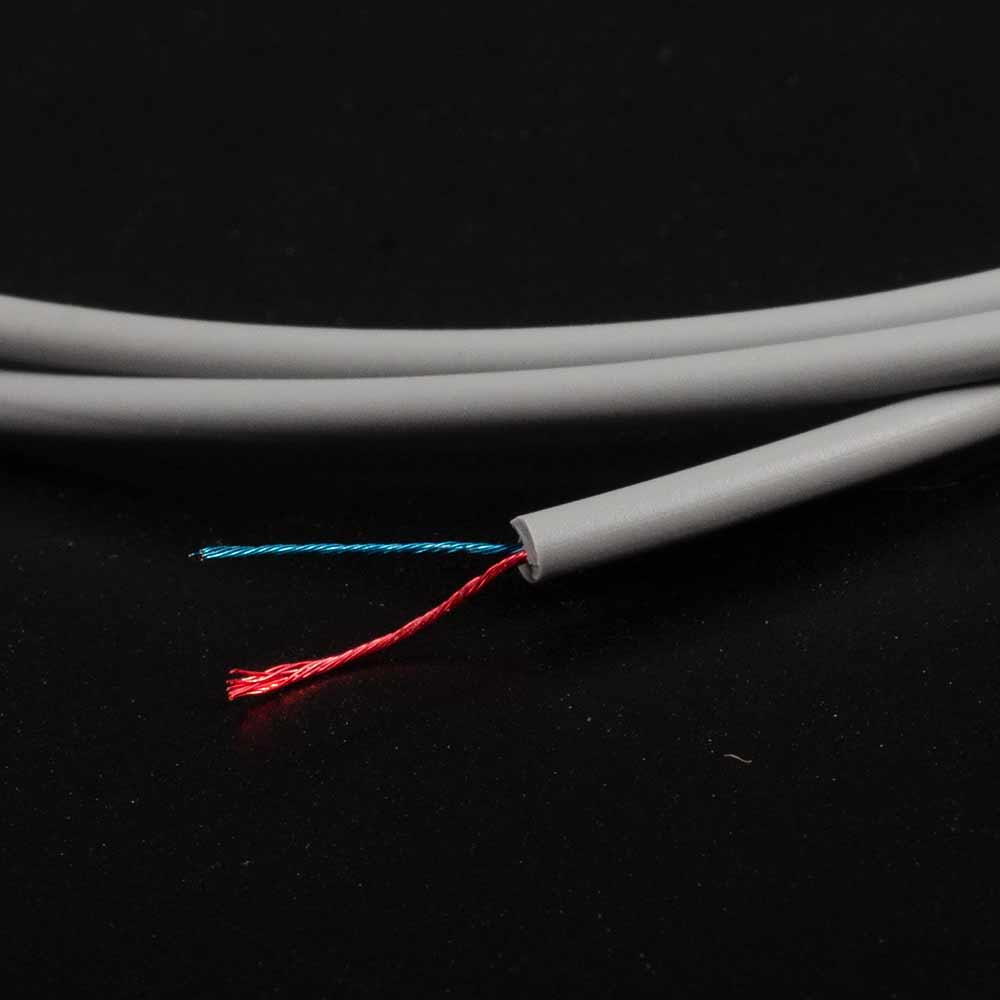

Can enameled wire be used as wire

Yes, enamelled wire can be used as a wire, but it has a thin layer of insulation coating that needs to be removed before use. The insulation layer is typically made of a thermoplastic material such as polyurethane or polyimide, which allows the wire to withstand high temperatures without losing its electrical properties. The insulation layer is necessary to prevent electrical shorts and to protect the wire from corrosion and abrasion. Therefore, enamelled wire is commonly used in applications that require a thin, insulated wire, such as inductors, transformers, and motors. If the insulation layer is removed, the wire can be used like any other bare wire.

The easiest way to remove paint from enameled wire

Enameled wire stripping is for the convenience of follow-up processing, such as tin plating, etc. Commonly used stripping methods include scraping paint removal method, concentrated sulfuric acid paint removal method, paint remover paint removal method, etc. Among them, paint remover is used for paint removal It can achieve labor-saving and time-saving effects. It is a method that is used more now. There are many different formulations of paint remover. The following is the simplest method of enameled wire paint removal and the formula and usage of enameled wire paint remover.

Enameled wire stripping refers to the paint on the surface of the enameled wire, which is usually operated with a paint stripper or special stripping equipment. The main reason for stripping the enameled wire is to facilitate tinning.

There are many methods for enameled wire stripping, and the commonly used and relatively simple methods are as follows:

1. Scraping paint

Paint can be scraped off one by one with a knife or a saw blade . When scraping, don’t just scrape the sides, but carefully scrape in a circle without scratching the wires. This method is too time-consuming and labor-intensive, and it is still possible if there are few enameled wires .

2. Concentrated sulfuric acid stripping

First soak in industrial-grade concentrated sulfuric acid , then rinse the black film with chromic acid solution, rinse with chromic acid solution, and then wash with water twice. This method requires concentrated sulfuric acid, which works well, but is dangerous to operate.

3. High-efficiency paint remover

It can quickly remove the paint, saving raw materials and labor. Organic paint can be stripped off in minutes from all metal surfaces. For the enameled wire that needs to be stripped, soak it in the paint remover for 0.5-5 minutes, the old paint film will swell and bulge, and then it can be completely peeled off. After taking it out, use high-pressure water to knock out the remaining paint flakes on the surface of the workpiece, and clean it with clean water.

Recipe and usage of enameled wire paint remover

When stripping enameled wires, the use of chemical paint strippers can save labor and time. Commonly used paint strippers have a variety of formulas:

1. Recipe 1

3 ml of formic acid, 2.5 ml of acetophenone, 0.5 g of paraffin, 0.5 g of plexiglass powder, 30 ml of chloroform, 2 ml of benzaldehyde, 2 g of benzoic acid, and 0.7 g of ethyl cellulose.

Usage: When the temperature is 25°C, soak the enameled wire in the formula 1 solution for 3~5 minutes, then wipe off the enameled wire.

2. Recipe 2

5 ml of formic acid, 5.3 ml of cyclohexanone, 4 g of benzoic acid, 1 g of plexiglass powder, 60 ml of dichloromethane, 1.5 g of ethyl cellulose, and 1 g of paraffin.

3. Recipe 3

200 ml of formic acid, 20 ml of amyl acetate, 10 ml of benzene, 40 ml of liquid paraffin. Usage: The processing methods of formula 2 and formula 3 are similar to formula -.

4. Recipe 4

20 ml of phenol, 10 ml of glacial acetic acid, and 20 ml of xylene.

Usage: At 70~75°C, put the enameled wire in the formula four drug solution, treat it for 2 minutes, and then wipe it with cotton soaked in ethanol. Or put the enameled wire on the cotton soaked in the formula four drug solution, and then use a tinned electric chrome to wipe and weld the enameled wire. All types of wires can be tinned directly by this method.

5. Recipe five

10 ml of phenol, 8-10 ml of formic acid.

Usage: When the temperature is 85C, treat it in this liquid medicine for 3 minutes, and the paint skin will fall off.

6. Recipe 6

6 grams of formic acid, appropriate amount of white wax, and 1 gram of banana water.

Usage: When the temperature is 85~90℃, treat it in this formula for 3 minutes to remove the paint skin.

Reminder: Formic acid, glacial acetic acid, phenol, bromine, hydrofluoric acid, etc. are highly irritating to the skin. Be careful when using them. If the skin comes into contact with these drugs, soak them in 70% ethanol first, and then roll them with cotton. After repeating several times, treat with 1% sodium carbonate.