How to choose Cable for overmold-TPE cable VS TPU Cable

Cable used in Medical devices interconnection or medical accessories can be silicone cable, TPE cable or TPU cable. Of course PVC cable can also be used, but usually for disposable purpose.in some countries, in order to save healthcare expense or environment, some medical items must be reusable, so TPU and TPE become two main medical extrusion or overmolding materials.As a tpu wire cable supplier,we have a large amount of TPU cables for you to choose,and Free sample is available for the items that we have stock

Then how to decide to choose TPU cable or TPE cable for your project?and how to judge which is TPU and which is TPE

To tell apart TPU cable and TPE cable can start from the main features of TPU and TPE and differences between them:

TPE Cable

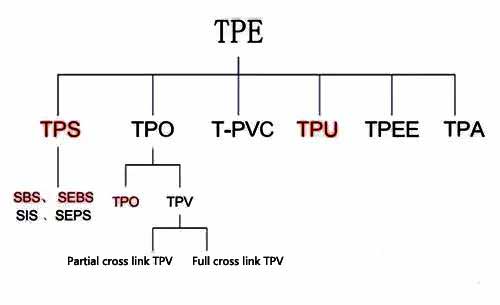

TPE(Thermoplastic Elastomer) is a Thermoplastic Elastomer (Thermoplastic Elastomer) material with high strength, high elasticity, injection molding, wide range of applications, environmental protection, non-toxic and safe, and excellent colorability. So TPE cable is an ideal option for medical interconnection.

Unlike Most thermosets elastomers, TPE is thermoplastic, need NO extra curing or vulcanization and can be directly used to extrude or injection overmould. TPE has good recovery ability after repeated stretching, it is an ideal material choice for items which value appearance much.

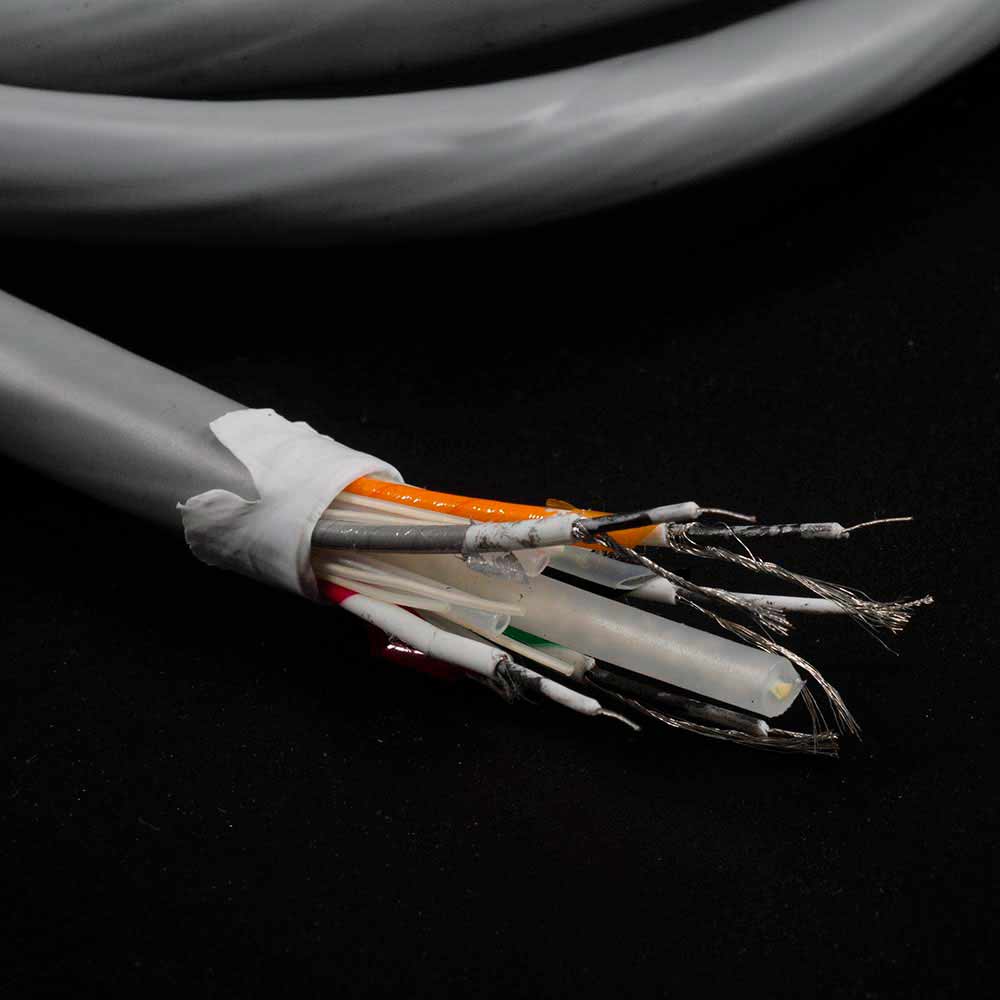

TPE can be used as insulation and Jacket

A shortcoming of TPE is its relative high cost, especially used for insulation since there are many lower cost options

TPU Cable

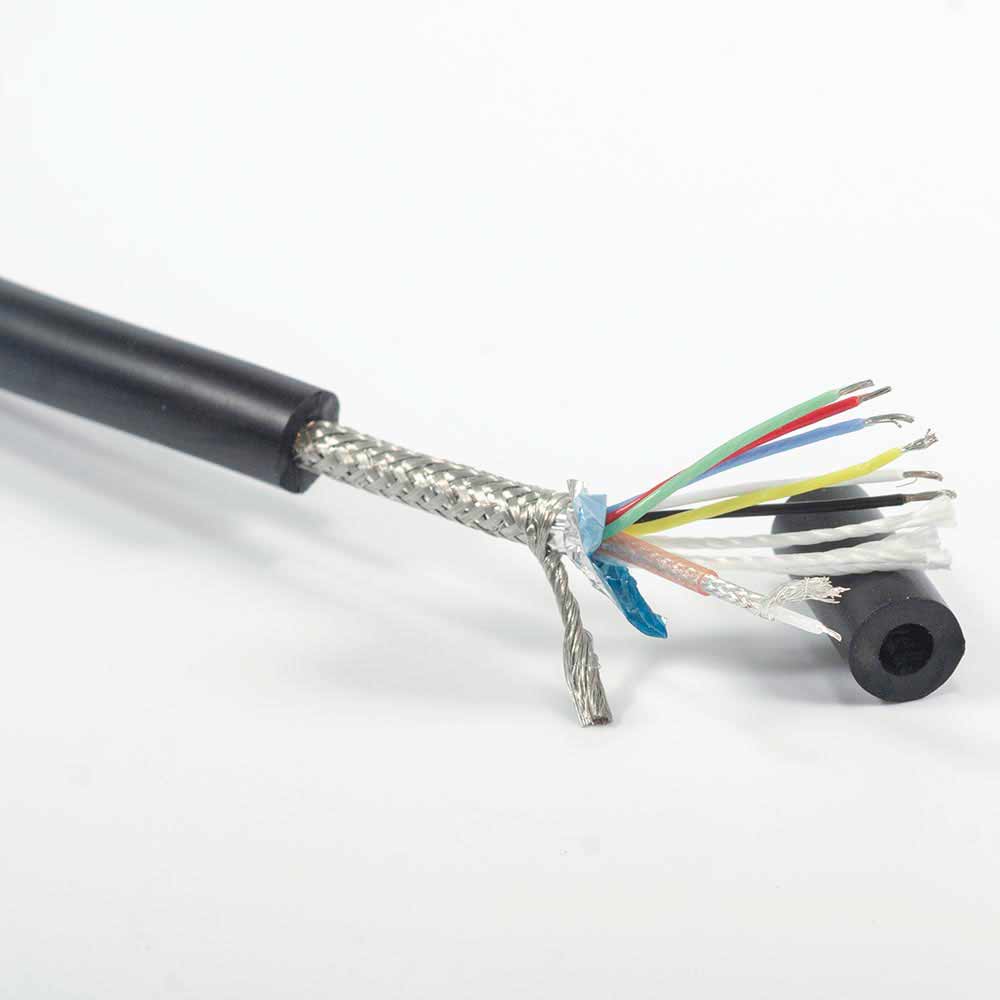

TPU (Thermoplastic Urethane) is a type of TPE with more improved properties,such as elasticity, transparency, oil resistance and abrasion resistance. TPU is a kind of polymer material composed of diphenylmethane diisocyanate (MDI), toluene diisocyanate (TDI), macromolecular polyol and chain extender. TPU Cable are used a lot in medical interconnection

The shortcoming of TPE is that TPU feels harder and its hardness range is narrow compared with other plastic materials. This feature also make The TPU cable torsion resistant anti-knotted compared with PVC, TPE, especially when the cable diameter is small, this advantage become obvious. TPU burns with a pungent smell, so do not burn it inside a house

As a medical tpu cable manufacturer,we manufacture TPU cable much more than TPE cable for reusable medial accessories.

Differences between TPE Cable and TPU Cable

The difference between TPE cable and TPU cable can be made from physical features and chemical features

Physical performance difference

Hardness

Generally speaking, TPE feels soft while TPU feels harder and rougher with strong friction.

TPE hardness range from 0~100 A Shore, in cable extruding field, the TPE cable usually range from 60A-85A.too softer is not suitable for cable extrusion.

TPU hardness range from 35~90A Shore (50~80D), the most common TPU cable hardness range from 75A-85A ,less than75A is rarely used in practice. 35~75A hardness TPU not suitable for cable extrusion, the cable appearance is hard to control during cable extruding and defective rate is higher ,so the final average cost for very soft TPU cable will be higher, sides of the softer TPU itself is more expensive.

Too soft plastic material, no matter TPE ,TPU,PVC or Silicone are usually used for sex doll or sex toys

Specific Gravity/density

In some application, the TPE cable is needed to submerge or floating on water ( floating cables for example), it is critical to choose the right density TPE materials.

The regular specific gravity of TPE ranges from 0.5 g/cm³ to 2.0 g/ cm³. Foamed TPE specific gravity is extremely low,is an ideal material to make floating cables or Low Capacitance cable

TPU density range is smaller than TPE, it usually range from 1.06 g/cm³-1.25 g/cm³;foamed TPU is not used as regular as foamed TPE

So TPU cables applications are not as wide as TPE cable. TPU cable is used a lot in medical field.

Mechanical strength

TPU cable has better mechanical strength than TPE cable, in term of abrasion resistance, resilience and wear resistance.

Temperature resistance

They are temperature sensitive materials

TPE Temperature resistance (-30 ℃ ~140 ℃) and Melt Temperature 220℃ – 240℃

TPU Temperature resistance (-40 ℃ ~100 ℃) and Melt Temperature 185 ℃- 220℃

These temperature range is ONLY for reference, different brands TPE/TPU or with different compound or processing will result in different features

Generally speaking, melt temperature of TPE is higher than TPU

This feature is very important for plastic injection molding:

For example, if you want to overmold a connector jacket for a TPU Cable with TPE, you will find that the TPE jacket cannot melt with the TPU cable, in this situation, if the cable need to be waterproof, TPE is not a good partner for TPU cable.

If you want to over mold for an ABS material connector, you will face a problem that the ABS connector shrink during the injection, in this application, PP connector is better than ABS.

So when you decide to choose TPU cable or TPE cable for Injection over molding purpose, it is better to have a comprehensive consideration.

Chemical performance difference

Resistance to oil

TPU has higher chemical resistance than TPE in many aspects, such as oil resistance, grease resistance.

Burning smell

TPE has a pleasant smell, however TPU has a pungent smell when burning

Tips for decision on choosing TPE cable or TPU cable

Generally speaking, when you are decide to use TPE cable or TPU cable, the application is the prior factor need to consider, especially for Industry application, the physical properties, chemical properties, even biological properties, processing and prices are factors must be considered

For daily use or commercial use, the general feeling of TPU cable is higher than TPE cable (if the hardness is the same. It may help business attract more user and bring good economic effect.

need a customize a TPU Jacket cable?

let TPU cable manufacturer to provide you custom solution

- All

- Blog

- Coil cable

- ECG cable

- Medical cables

- raw cable