Low Noise Cable

What Is Low Noise Cable?

A Low Noise cable is processed by using specific construction techniques and material selection in addition to conductive dissipative layers in order to decrease and reduce electrical noise induced by mechanical stress on the cable ,which is called Triboelectric noise.

when either standard or custom cables experience mechanical shock, the individual layers move relative to each other (conductor and shield move relative to insulation). This movement charges the insulation, creating a charged capacitor that results in a voltage difference between two conductors or a conductor and shield.

When we know the cause of the noise,we can find some way to reduce it and make low triboelectric noise coaxial cable.

Typically ,A conducting layer is added to the surface of the core wire insulation(paiting for extruding). This layer is bonded to the insulation preventing movement between the two different materials ,so as to prevent charging. Charging caused by movement between the low noise coated primaries and other components of the cable is dissipated immediately preventing a voltage difference.

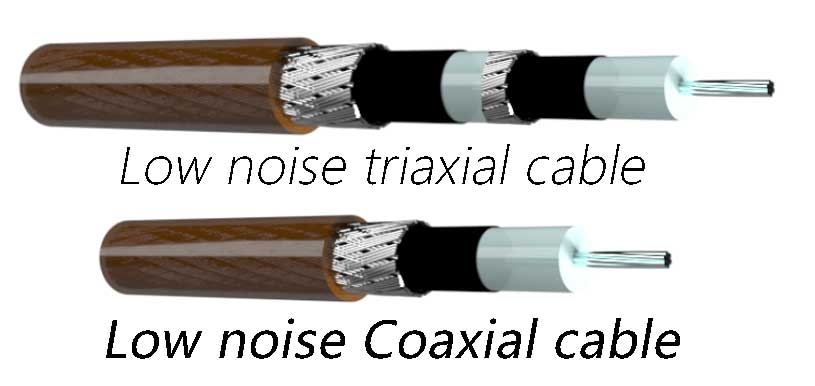

Typical Low noise cable includes low noise coax cable (such as low noise bnc cable for CCTV or home television) and low noise triax cable

>>>>Find More Low noise cable family based on Different structures and cores!!!

4 typical structures of Low Noise cable

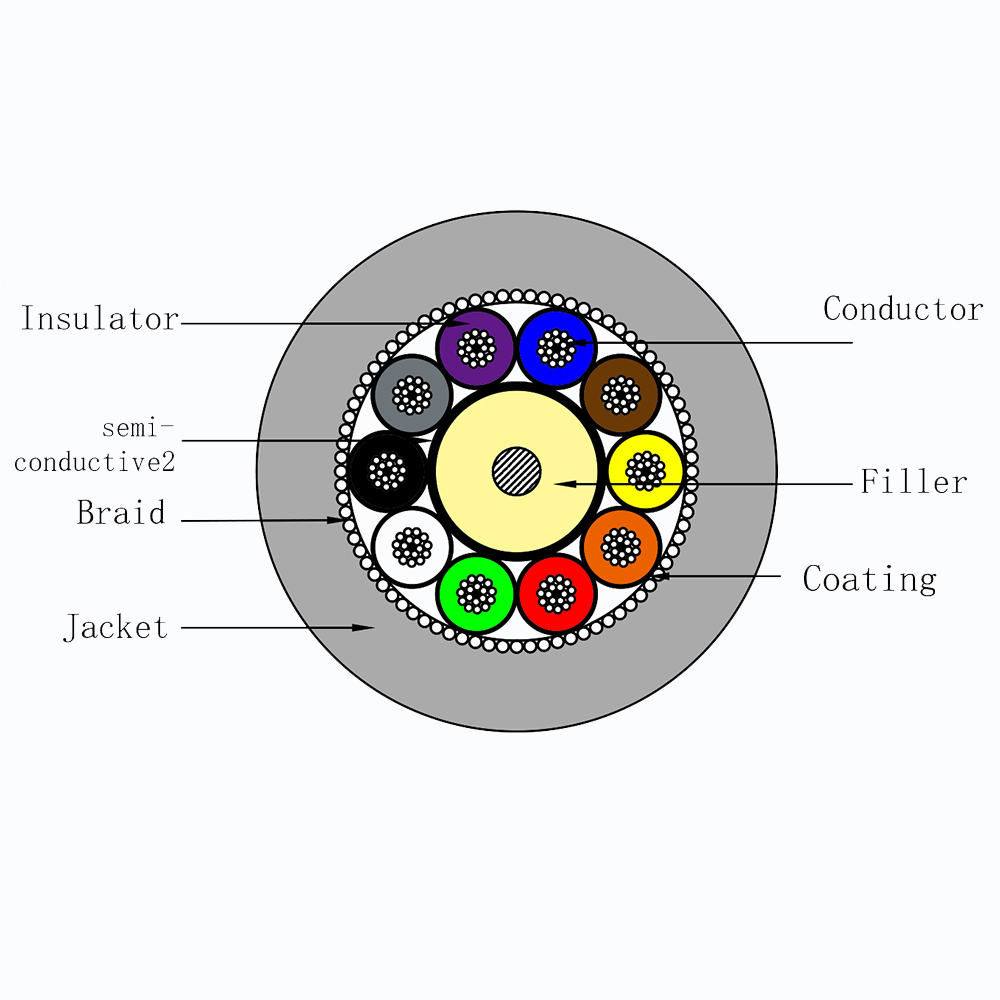

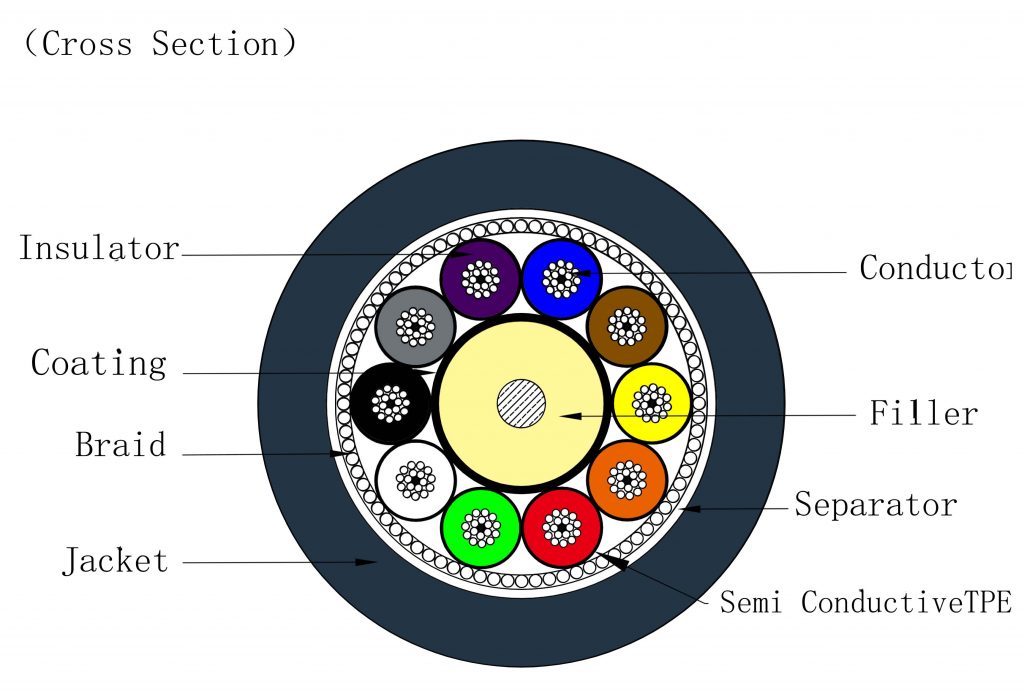

Type 1:each wire with separate low noise layer and separate Shield

this is structure of EC206S-001 developped by us for medical purpose,whose Noise value is around 25uv.

The advantage of this structure low triboelectric noise coaxial cable

1,Flexible,coaxial structure,Kevlar as filler,outer shielding layer

2,very easy to define the cores according to is inner jacket color

3,Low noise Level:less than pk-pk<50µV

the disadvantages

1,the processing steps are too many,this cause the high procesing cost,so the total cost of the cable increased

the price of low noise medical cable like this usually is 2.5-4USD/meters( depends on different products specification)

2,the OD can not be made as thin as want,as the comprensive structure( independant shielded,semi conductive layer coated for each core).when the cores are not much,this advantage is not obvious,if the cores reach 10 core,12 core,18 cores even more,then this structure is a problem.The applications determs the OD can not beyond a certain value.

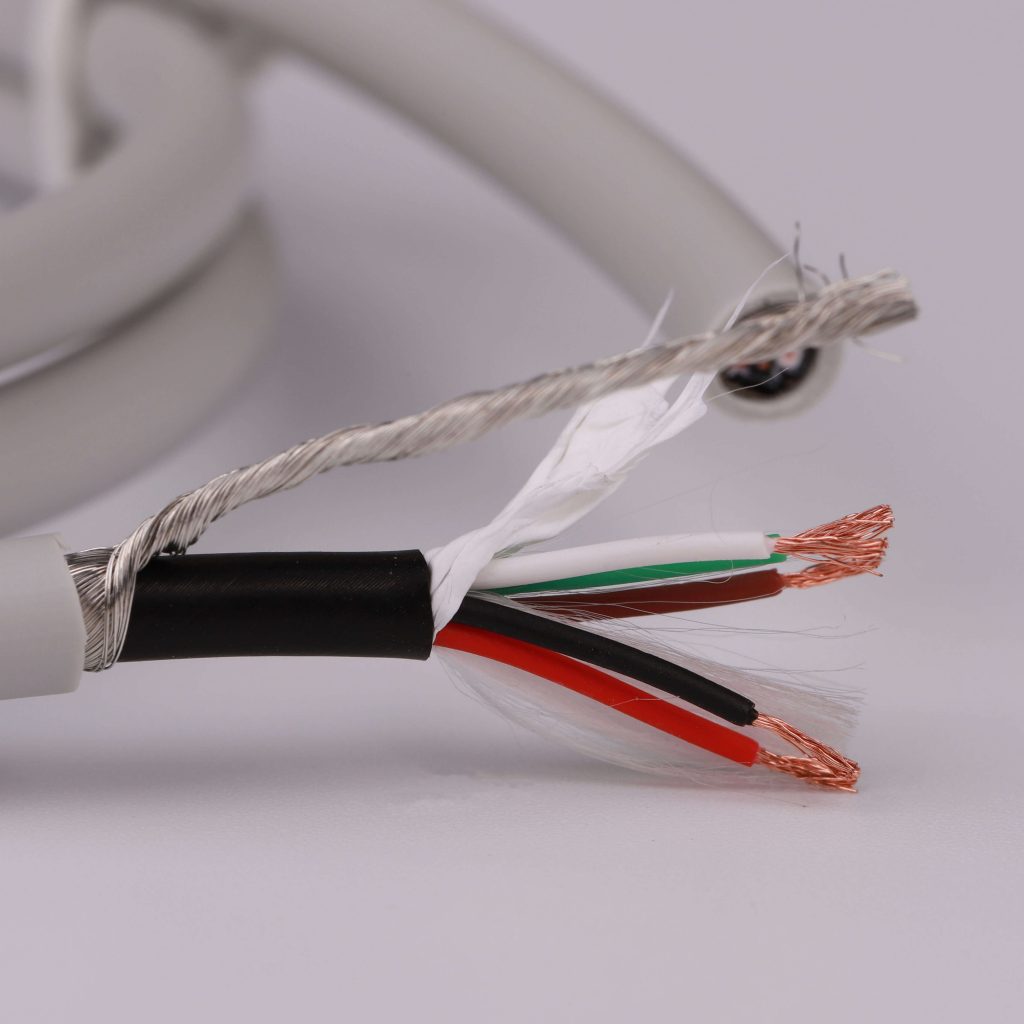

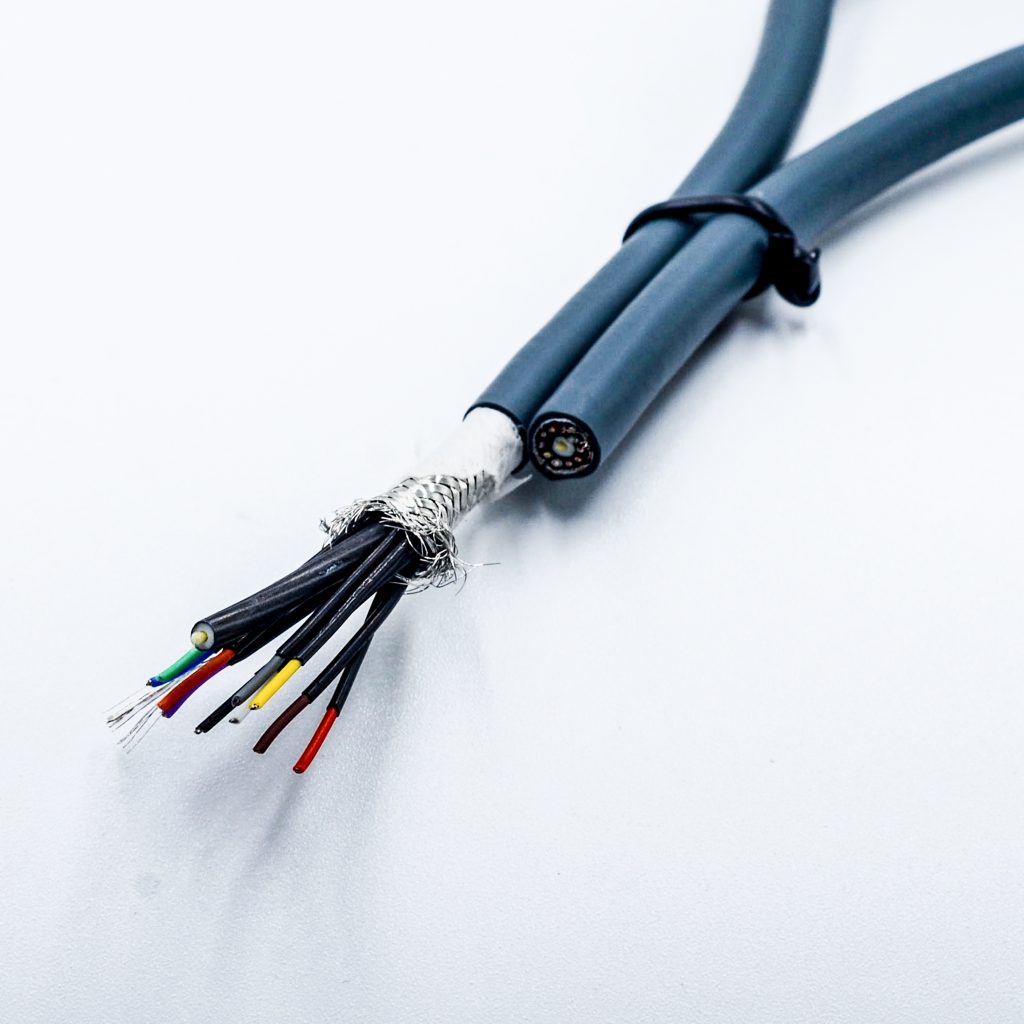

Type2:wires separate coating low noise layer and one overall shield

Graphene wire:In order to overquer the disadvantage of Type 1 low Noise cable coaxial ,A Second realizing way- new technology is appealed to applied.we call it “coating” based on conductive”graphene mixture”

Compared with semi-conductive layer(TPE),whose resistance is 10^5,graphene is a perfect conductor .Graphene mixture is not a Plastic material,it can not be extruded as normal Plastic material like TPU,PVC…

The “coating” is time-consuming processing,there is not any tutial on youtube or anywhere else.and the recipe of the graphene mxiture is also a technical secret. what is worse,Graphene is a newly developped material,so graphene wire,s cost is much higher than silver wire,and copper wires

Medical cable manufacturers are always facing a technical chanllenge,that is More complicated structure,more and more functions demanded,better and better performance required….But the maximum accepted OD are thinner and thinner

EC210S-005 is a Low Noise cable with appointed OD,the tradtional processing method can not meet is requirement.so a new technology” Coating” is applided in it.from its appearance,there is no much difference from a common 10 lead ECG cable,But its Low Noise performance is less than pk-pk<50µ

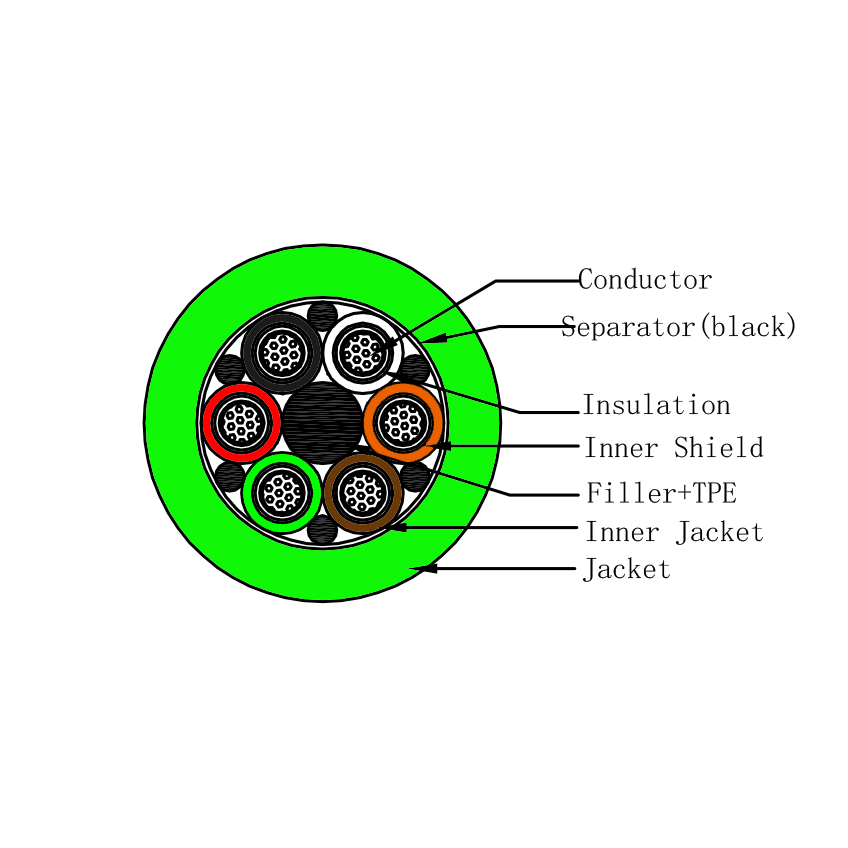

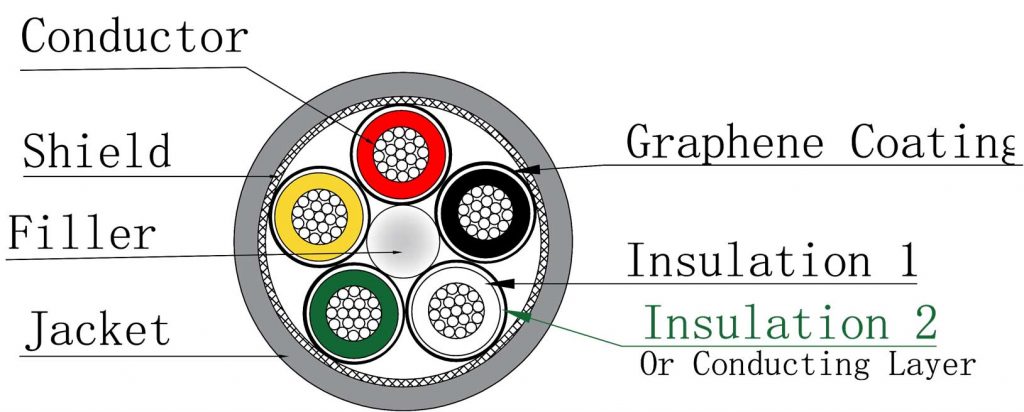

Type 3:Separate Extruded Low Noise Layer And One Overall Shield

A third Low Noise cable realizing way is for those who does not master chemical stripping or do not want to use chemical stripping .Its structure is as following diagram shows:

This structure combines the advantages of the first two method:

- in a limited outer diameter ,cover as many cores as possible.

- Conducting layer is easy to be removed

- Good Low noise effect

Type 4:Newly developped Easy strip graphene low noise cable

As mentioned above:graphene coating need chemical striping,it is time costing; the noise performance of Extruding low noise layers cable is not ideal as expected. These are the disadvantage for them. To conque this problem,a forth newly developed way conbines their advantages,and bring new features:

1)the conducting layer/insulation 2 can be as thin as possible,which make small OD low noise cable possible

2)as the graphene coating layer is on the conducting layer/insultion 2,so it can be merchanically easy strip and no more risk of short circuit.

There are some other trial,which are intended for easy stripping.It is developped on the earlist Low Noise structure,whose Low Noise layer is a overall semi-conductive PVE or PE.

Based on the thought that:grephene plated TPFE tape or metal Shielding cloth can closely wrap the wires and better conductivity than semi-conducting PE/PVC. However the result prove its noise performance is not as good as Type 1 and Tpye 2

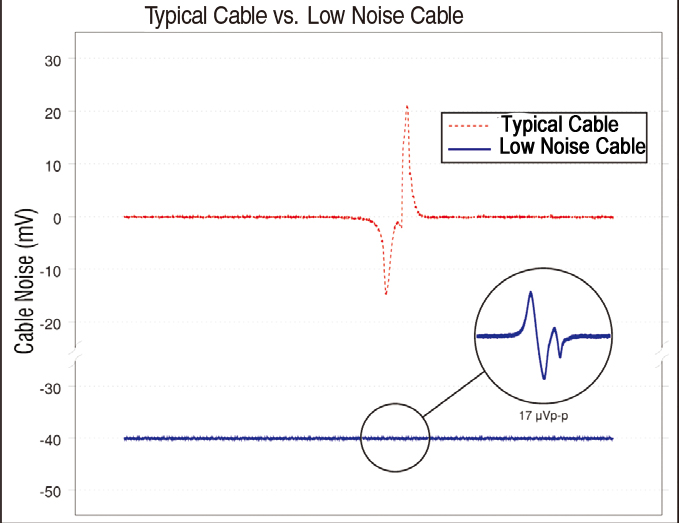

Comparison of Typical cable and Low Noise Cable

With traditional cable, simply flexing or twisting can generate voltage spikes with magnitudes in the tens of millivolts. Cables utilizing our low noise extrusions and coatings typically see voltage spikes decreased to the microvolt range. We can work with you to select the low noise option best suited to your application.

Applications of Low Noise Cable?

With sensitive signal applications it is essential to utilize transmission lines which limit noise. This is particularly difficult in applications where a cable experiences mechanical shock, vibration, or repeated flexing during use. To combat these concerns YQF offers several low noise options designed to maintain signal integrity.

The Triboelectric Effect is a process by which dissimilar materials can acquire an electric charge through contact. In wire and cable this effect can alter baseline voltage levels or the insulation can act as a capacitor temporarily storing the charge until it is released as a voltage spike. The addition of conductive layers, careful material selection, and special manufacturing techniques can reduce noise by dissipating this charge.

Low triboelectric noise coaxial cable(coaxial and multi-conductor cables ) has its absolutely advantaged in the application of small-signal transition where shielded cable will suffer mechanical shock,such as twisting, crushing, flexing, pulling, etc.

Following situation,Low noise cable are strongly recommended:

- Medical Instrumentation( and Accessories),such as ECG, EKG,EEG,Endoscope, Pulse Oximetry

- Microphones

- Test and Measurement

- Sensors

- Measurements of low currents down to femtoamperes

- Photodetectors and ionization detectors

- High resistance measurements

- Scanning probe microscopy (STM, SPM, STS)

- Spectroscopy

- Piezo- and pyroelectric transducers

How To Do Low Tribolectric Noise Testing

The standard we adopt in our Shielding room for Low Noise testing is ANSI/AAMI EC53:2013 5.3.2 . This Standard has a requirement for the Tested Sample to generate less than a 50 uV of triboelectric noise between signal wires when the sample is mechanically manipulated. Most of our Low Noise Value is around 20-24uV. Being a long time preferred supplier to many Medical Product Manufactures, Systems Wire and Cable has refined its manufacturing processes and also draws from our many years of accumulated knowledge in this challenging field.

Tips:Chemical way to strip a “Coating" coated Low Noise cable

How to strip a “coating” Low noise cable is very crutial to the safe of production,the quality of a products.

For Coating low noise cable,an automatic stripping and cutting machine,can not help you,as an medical cable manufacturer,we tried many ways when we develop this cable,we find Chemical stripping is the best way.

The outer low noise layers must be stripped back at least 1/8” to ensure that shorts do not occur between the conductive layer and the conductor. Recommended chemicals include: citrus solvents, mineral spirits, and MEK.