Medical TPV cable with Santoprene 8281 med series TPV

Santoprene 8281 Med series TPV has different hardness,range from 35A to 90A,especially 8281-65MED is widely used in USA medical equipment.

Santoprene 8281 series TPV includes:

- santoprene 8281-35med

- santoprene 8281-45med

- santoprene 8281-55med

- santoprene 8281-65med

- santoprene 8281-75med

- santoprene 8281-90med

the advantages of medical TPV cable

TPV medical cable give user a cyberskin feeling,and TPV combines the features of Rubber and Plastics.The main application of TPV in the medical industry is pharmaceutical rubber stoppers. The production of traditional medical vulcanized rubber plugs produces a large amount of corner waste (about 15%), resulting in a lot of waste of raw materials; in addition, there are many problems such as high energy consumption and low production efficiency in the processing process. Therefore, in today’s increasingly tense energy environment, it is of great significance to develop thermoplastic elastomer materials to replace traditional medical vulcanized butyl rubber. Medical TPV (thermoplastic medical bromobutyl material) is an ideal substitute material for traditional medical vulcanized butyl rubber stopper. Thermoplastic medical bromobutyl rubber material not only completely solves the problem of waste of scraps of medical vulcanized butyl rubber stopper, but also can The cost can be greatly reduced by multiple molding processes; and the thermoplastic medical bromobutyl material can be molded by thermoplastic processing, which greatly reduces energy consumption and improves production efficiency,reduce carbon emissions

The physical properties and functions of TPV at room temperature are similar to those of thermoset rubber, and it exhibits the characteristics of thermoplastics at high temperature, and can be processed quickly, economically and easily. TPV thermoplastic EPDM dynamic vulcanized elastomer/rubber The vulcanized rubber material is dynamically vulcanized to make the EPDM EPDM dispersed in the polypropylene PP plastic matrix with particles below 2 microns in size, and the characteristics of rubber and plastic are very good. Combined together, a high-performance elastomer material with excellent comprehensive properties is obtained.

Medical TPV cable main performance:

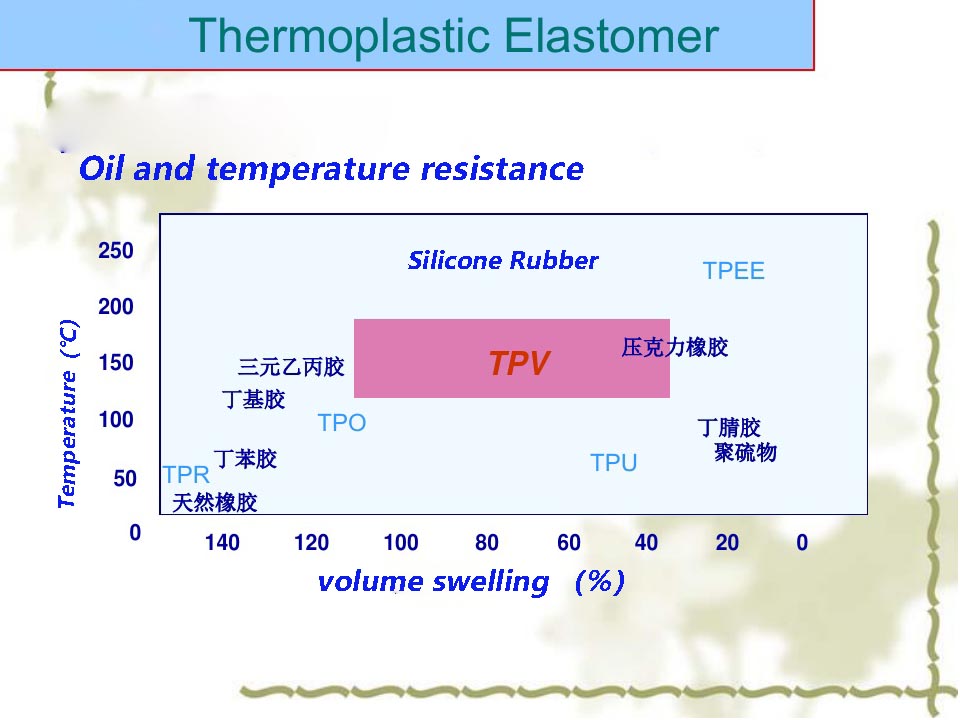

- TPV can be used in the temperature range of -60c-135c, and the application temperature range is wide;

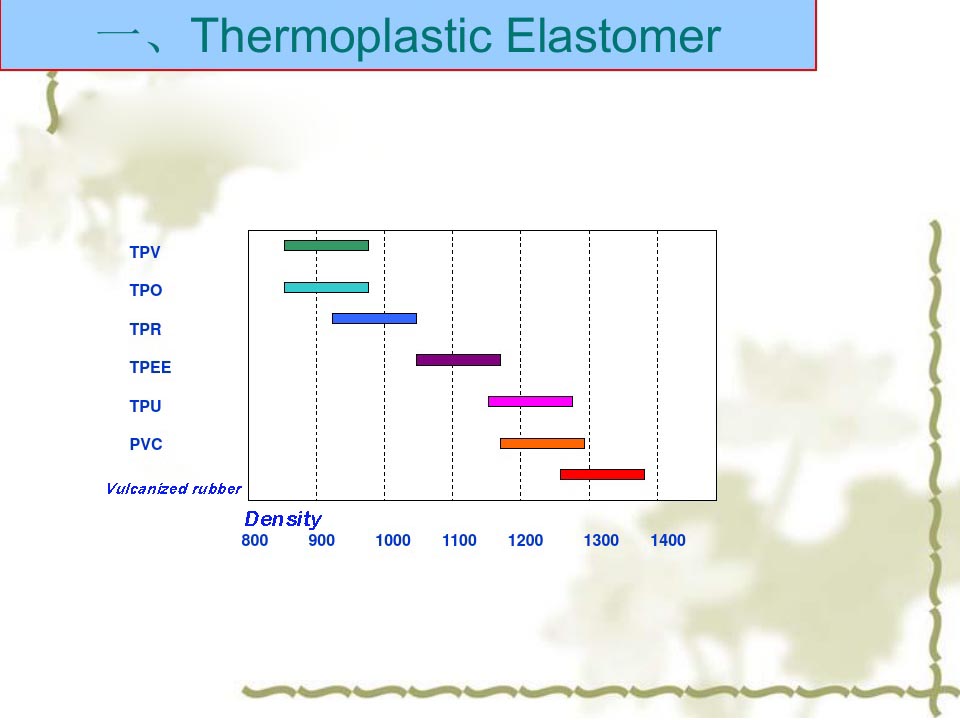

- The TPV hardness range is between 25A and 65D, which can meet a wide range of hardness requirements;

- TPV has good weather resistance, excellent anti-aging, ozone resistance and UV resistance;

- TPV does not need vulcanization when used, and can be directly processed by injection, extrusion, calendering, blow molding, etc., which can shorten the processing process and reduce processing costs;

- The environmental resistance of TPV is similar to EPDM, and the oil and solvent resistance is similar to that of neoprene;

- TPV is easy to weld, reusable, environmentally friendly and non-toxic.

Main features of medical TPV cables:

- Excellent anti-aging properties and good weather resistance and heat resistance;

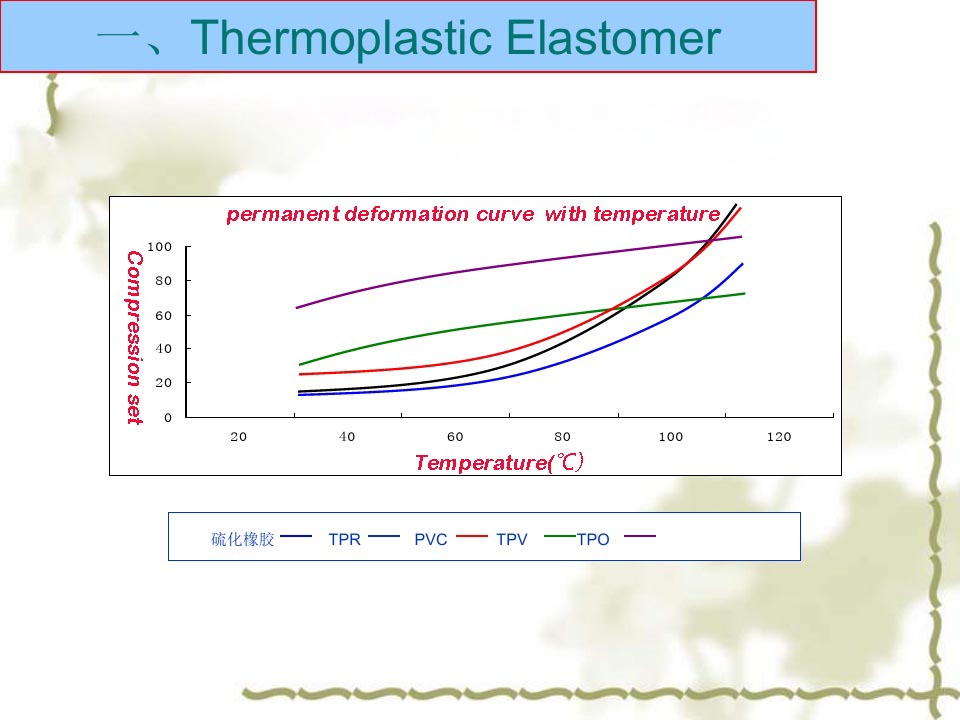

- Excellent resistance to permanent deformation:

- Excellent tensile strength, high toughness and high resilience;

- Excellent environmental performance and reusable

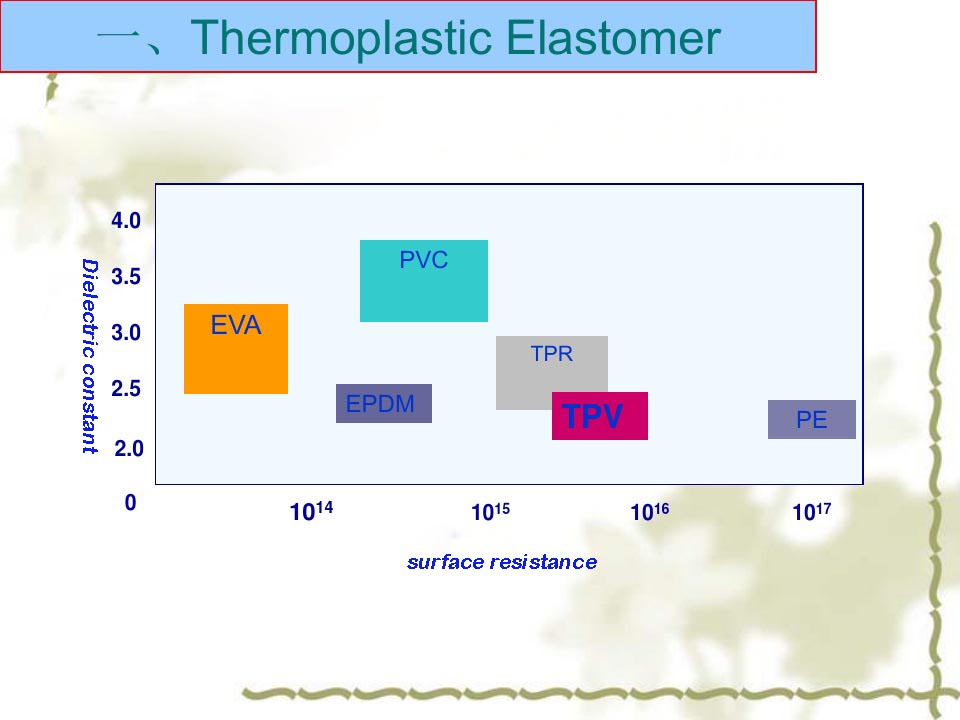

- Excellent electrical insulation performance;

- A wide range of hardness;

- A wide range of operating temperatures;

- Various colors, full transparent, translucent, light-colored series, easy to color, easy to process and shape;

- Can be combined with Co-injection or extrusion molding of PP, PA, PC, ABS, PS, PBT, PET and other materials.